Revolutionize Your Fleet with Black Iris powered by Perfomax Leading the Way in Maritime Innovation

Digital noon report

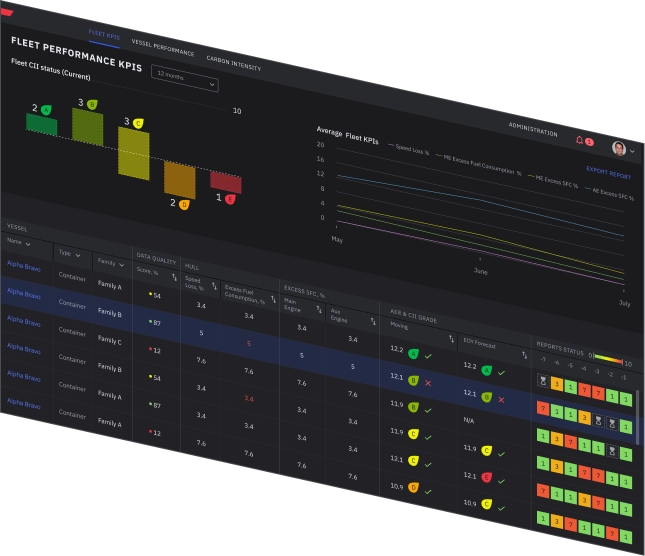

Manual input time cost reduction Cross-check of the reported parameters Pre-fulfilment of the reports Transformation of the Excel/email reporting into digital dashboards

Vessel Performance

ISO-compliant digital twin methodology Data quality smart analysis Hull, ME, AE smart monitoring Smart notification system

CII

End-of-the-year forecast Simulation tool to assess power limitation and ESD’s Real-time trend analysis and compliance decision support Onboard consumer’s contribution analysis

Reporting

End-of-the-year forecast Simulation tool to assess power limitation and ESD’s Real-time trend analysis and compliance decision support Onboard consumer’s contribution analysis

Black Iris (Powered By PerfoMax) powers classical naval architecture and marine engineering methodology with Digital Twin and AI technologies.

- Adjustments of the models on ship design data,

- Numerical naval architecture and marine engineering methods compliance,

- Advanced accuracy with regression models and modern algorithms

We aggregate ship operational data, enrich it with specific industrial data sources and process with modern algorithms to deliver the best accuracy analysis for performance monitoring, emission analytics, and energy efficiency optimization.

FAQ'S

What vessel types might use the Black Iris (Powered By PerfoMax) platform?

Black Iris (Powered By PerfoMax) functionality covers all types of vessels while having special extensions for offshore, bulk, container, and tanker vessels.

What data sources are used for the analysis?

Black Iris (Powered By PerfoMax) is a flexible tool that offers functionality on the basis of different data sources like noon reports, sensors, satellite data, and industrial databases. Our goal is to deliver the highest possible accuracy of analysis with the available data.

Do you install the hardware onboard the vessels?

Black Iris (Powered By PerfoMax) is a sensor-agnostic platform, we could recommend sensor types or specific IoT devices. We could support the installation process with our local partners in the EU, MENA, and APAC. We don’t have preferable suppliers and our mission is to make your digitalization process cost-efficient and transparent.

I use Excel for analysis, what benefits we will get from Black Iris (Powered By PerfoMax)?

Vessels operate in varying conditions, whether it is the loading conditions, usage of fuel types, or weather conditions, which makes all the data incomparable. Black Iris (Powered By PerfoMax) uses advanced algorithms to bring your data to an “apple to apple” comparable state, where data can be used to its maximum potential. Excel lacks the necessary capabilities to process such a modeling.

How Black Iris (Powered By PerfoMax) take care of data quality?

We utilize statistical methods fused with a grey-box digital twin approach, where unrealistic data or data with high deviation from ideal behavior is flagged, and further same could be used for noon report and MRV-DCS data rectification, identifying faulty data streams from telemetry system or catch suspicious events like manual fudging of data.

What is a Grey-Box Performance model, and why should it matter to me?

What vessel types might use the Black Iris (Powered By PerfoMax) platform?

What data sources are used for the analysis?

Do you install the hardware onboard the vessels?

I use Excel for analysis, what benefits we will get from Black Iris (Powered By PerfoMax)?

How Black Iris (Powered By PerfoMax) take care of data quality?

What is a Grey-Box Performance model, and why should it matter to me?

Grey-Box Performance models use the ship-specific design data to model performance behaviour which is then enriched with real-time noon reports or sensor data to understand vessel performance. This approach allows our clients to achieve trustworthy performance metrics with basic data like daily noon reports.

Other methods like Black-box models need big-data sets of high quality (long-term telemetry data) to model ship performance and are highly biased to the data quality, however, with a grey-box model, this bias could be avoided.

How Black Iris (Powered By PerfoMax) could help me with Emission monitoring and reduce CII?

Black Iris (Powered By PerfoMax) provides a comprehensive overview with emission monitoring from major onboard consumers, overall Annual Emission Ratings(AER), advanced end-of-the-year prediction, and CII grade simulation based on parameters like fuel change, additional non-sailing time, Energy saving device or EET installation, etc.

As Emission Ratings are calculated based on sailing distance, it is crucial to monitor the impact of non-sailing time on overall CII, and our in-house developed metrics like moving AER help to understand the impact of overall operations over time.